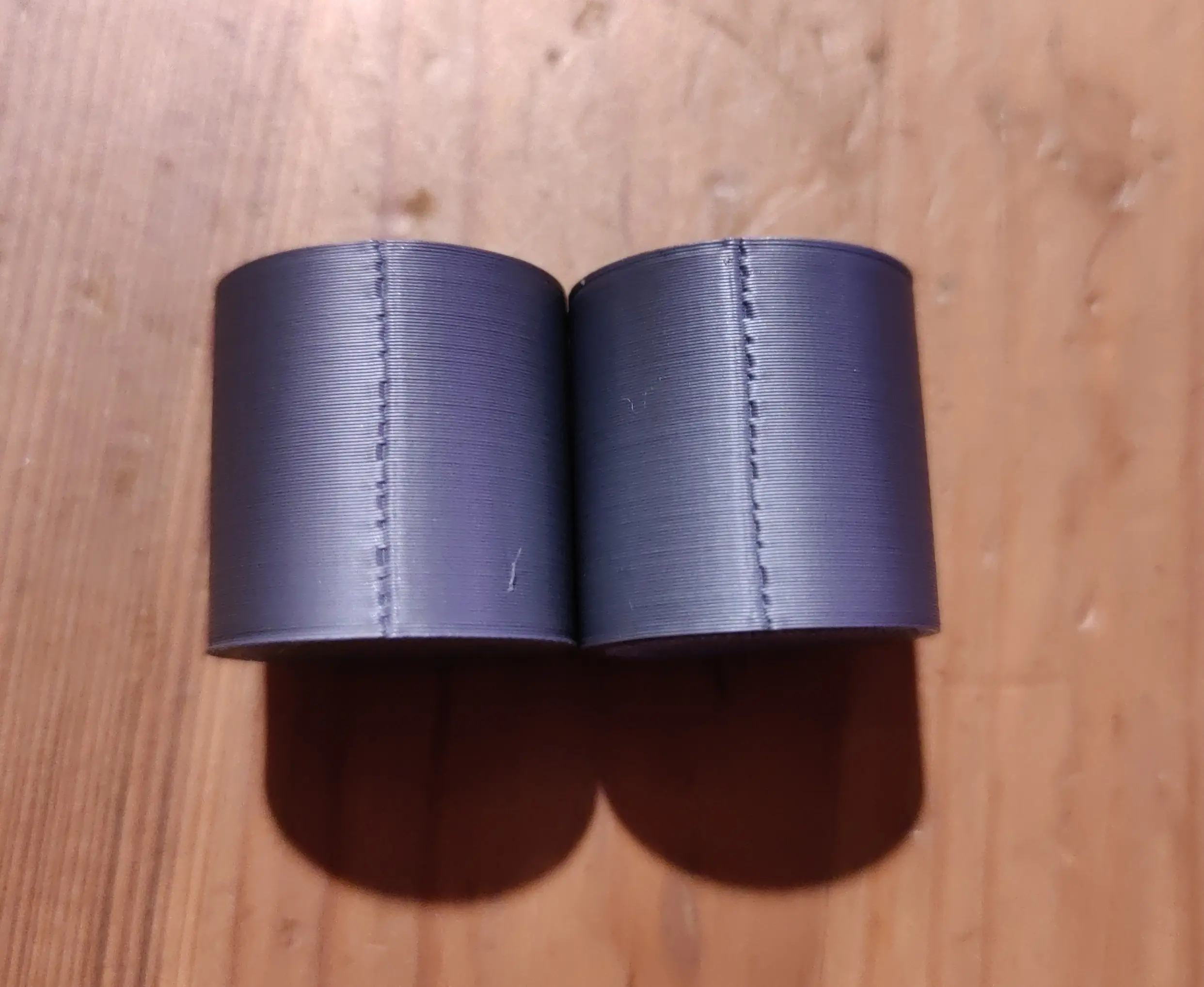

There is a setting in super slicer called Seam gap, do you see a setting like that you can play with?

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

Yes I've already tried that, and it doesn't make much of a difference.

Disclaimer: I'm not into 3d printing. I'm just a wannabe with not enough time on my hands, so take this post with a bucket of salt. I have, on the other hand, worked a lot with automated machinery.

But if I were to make a guess, I would suspect some slack in either the X or Y direction, resulting in inaccuracy when the nozzle changes direction. This should in theory be less visible when the nozzle is not making sharp turns.

Are your belts tight? Any gears with poorly meshed teeth?

Also, are you able to turn the print (and the seam) 45 and 90 degrees? Do they show up just as ugly? If not, the issue is mechanically limited to one axis.

Actually yeah, you might be on to something there. OP could try adjusting belt tension.

If you do end up adjusting belt tension though, make sure to recalibrate your e-steps after.

That retract distance seems a bit low to me. My (direct drive) printer is happier around 1mm to 1.5mm. I'm not convinced that has anything to do with your particular problem, though.

Anyhow, to my untrained eye that looks like underextrusion at layer change and/or the perimeter lines not actually hitting each other. Are you sure your pressure advance/linear advance values are correct for that filament?

Also, does Orca Slicer allow you to specify a negative value for the seam gap? If so, that might be worth fooling with to see if it has any impact. That's probably a band-aid, though. I think your issue lies in pressure advance tuning still.

This is the filament I've tuned PA with, and to my best ability this is what Elli's guide suggests is the optimal value 🤷♂️

But I agree, it does actually look like PA is tuned incorrectly and stopping extrusion too soon/starting it too late.

Randomize Z seam and make sure your flow/retraction settings are as good as you can get them.

Messing around with your nozzle temperature might help too: Keep in mind that the thermistor in the heat block might be off by a few degrees so if you can measure the temperature directly as a comparison, it can help you figure out how much it's usually off by and adjust accordingly.

Randomised seams just spreads the issue out on the entire model surface, it looks even worse like that.

It will probably help more once your settings are dialed in, otherwise, yeah it's just going to distribute the mess. Alternately, keep everything as is and fix it up post-print via filler and sanding.

That's a really weird looking z-seam, something is going on there that I'm not quite sure the cause of.

However, in this case I think you could try randomizing z-seam position. It's not gonna fix the issue completely but it might help you with this particular part.

Yeah I've tried that, but it's still really bad, almost worse, with these scattered all over the surface.

Yeah I thought that might happen too. I've never seen seams like that before. What temp are you printing at?

It's printing at 200C with fan at 100%, using a 0.4mm hardened steel nozzle.

Have you ever done a PID tuning?

Yes, I recently switched the hotend from a proprietary one to a regular volcano hotend and did PID tuning.

Did you notice this kind of thing happening before you switched your hot end? I'm assuming you've tested printing at a higher temp already but I have to ask anyway. 200C is kinda low for some PLAs.

Yeah I've tried 190-220C, which is the range specified by the manufacturer of the filament.

I don't remember seeing this issue before the change, but I'm still new to the hobby and may just have overlooked or accepted it earlier.

Is there a way I could see the file you're trying to print?

This is just the basic cylinder that's part of orca slicer that I'm using to troubleshoot the issue because it's quick to print and the issue is clearly visible.

New Lemmy Post: How do I fix these god-awful seams? (https://lemmy.world/post/12523802)

Tagging: #3dprinting

(Replying in the OP of this thread (NOT THIS BOT!) will appear as a comment in the lemmy discussion.)

I am a FOSS bot. Check my README: https://github.com/db0/lemmy-tagginator/blob/main/README.md