3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

Hmm, I've never tried OrcaSlicer. I'm curious, installing it now.

I did also switch to orca around the same time I changed the hotend...I'll give my old slicer a go as well, maybe it's a slicer issue.

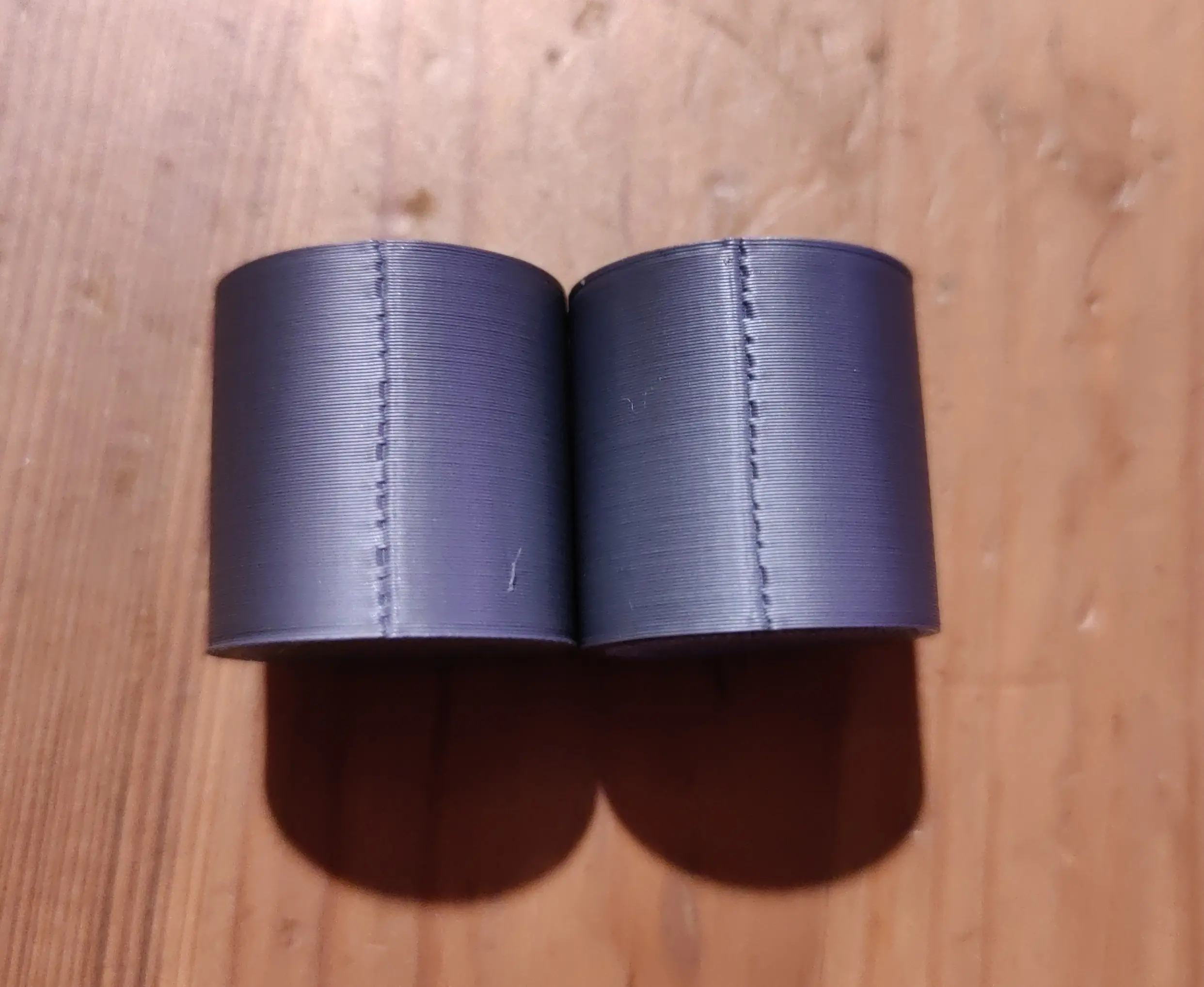

Well, I just printed a cylinder and my seams are just fine with "default settings".

I say "default" because originally I saw some weird stuff in the preview but it turned out to just be because for some reason spiral vase mode was on by default.

I just noticed, after intensely staring at my print from an awkward angle to see the nozzle while printing, that the gyroid infill has an anchor to the wall at the seam line. What kind of infill and infill settings are you using?

Actually noticed my settings were not "default" at all because I had selected options in the calibration test section. I just started an actual default print with a top, bottom, multiple walls and infill hahah.

I'm printing with grid infill. Gonna cancel and try with gyroid.

I'm getting a 100% uniformly bad seam with grid infill, instead of the one in the pictures that kind of "switches side", which in guessing is because of the direction changes relative to the wall made for gyroid throughout the model, but grid always moves away from the wall at the same angle.

Edit: tried without any infill, same result as grid infill. So it's would seem it finishes the wall before it actually fully connects the wall-end to the wall-beginning on the outer walls, before changing to next layer or infill.

Yeah I got the same thing where it seems to pull when it's switching direction but it's nowhere near as bad as how it is on yours. I'm thinking it might be a physical issue with your printer.

Yeah you're probably right...I'll take a looks at the motion system then

Hopefully it's not too much of a pain in the ass, or at least leads to a fix. Good luck!

Could you tell me where in OrcaSlicer you found this cylinder? I can't seem to find it in the calibration tests.

Edit: Nvm found it hahah

Yeah that's definitely a possibility. I'm just finishing up my start g-code, gonna see what happens if I try to print that cylinder. Hopefully my printer doesn't blow up or something 🤞