3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

In what can only be described as "perfect timing", the 3d printing channel teaching tech uploaded a video about just this problem literally a day ago: https://youtu.be/vl0FT339jfc

Yeah I can see that the seams of his "before" models is actually look like what I've been able to achieve on mine now. I guess I was trying to fix the last bit with standard seam options which might not have been possible.

I'll download the noisyfox orca slicer and test the scarf seams out.

Here is an alternative Piped link(s):

https://piped.video/vl0FT339jfc

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I'm open-source; check me out at GitHub.

Is the bad side of the seam where it stops or where it starts printing the outer wall? I assume it's where it stops and then it cross the wall to form the infill?

To add to the PA questions, are you sure that your PA setting actually are changing anything?

What printer is this and what firmware?

Does a spiral mode print work fine?

What if you print the part significantly slower (to rule out rigidity/acceleration issues)

Is the bad side of the seam where it stops or where it starts printing the outer wall? I assume it's where it stops and then it cross the wall to form the infill?

Correct, but this still happens when printing without infill, although less.

To add to the PA questions, are you sure that your PA setting actually are changing anything?

When printing the PA pattern, I can clearly see a difference. I haven't seen a huge difference in the actual print quality. It doesn't seem to have the any effect on this issue.

What printer is this and what firmware?

It's an anycubic kobra 2 bedslinger running klipper

What if you print the part significantly slower (to rule out rigidity/acceleration issues)

Tried printing at both 30mm/s and 100mm/s, it looks the same aside from slightly worse ringing at the higher speed.

What printer do you use. This is a mechanical issue. It's something binding as the one x or y is traveling could be a bearing or the stepper motor it self. It prevents the arc from being fully formed even though the machine thinks it is key point you made is that randomized z seam leaves the same mess, but if notice it's not all the layers are cut short only some.

Take the belt off and move the axis by hand slow and easy do you feel anything that isn't smooth like silk? That would be it. Feel the stepper is the drive gear tight any slip ?? Any play in the shaft side?

Edit

Looking at the pictures again I'd bet that if you went taller and printed faster, it would be even worse because the bad part got hotter and more bound up more Alternatively printing faster might make it better because you have the inertia to push past the binding spot.

It's an anycubic kobra 2 running klipper.

Randomized seams leaves the same mess, but randomly distributed around the model and not aligned like in the picture. But each seam is equally bad everywhere on the model.

Speed doesn't seem to affect the issue, I've tried both 30mm/s and 100mm/s

I disassembled the X and Y axes yesterday to check the motion system, moving by hand seems as smooth as it's ever been, no slip that I could feel. I think one roller on the X axis is very slightly oval unfortunately, but moving the model to different locations have no effect on this, and rotating models so seams align differently on the axes doesn't change anything, so I don't think that's the source of the issue.

Can you post the g code ?

I'll post it later today

I have one just like that on my scrotum and was told it's normal so I wouldn't worry about it too much.

Yeah it's just part of the injection molding process.

Actually, it's part of the vulva closing process.

I wouldn't know anything about that.

Have you tried being nice to the mold for a start?

So I stared at this for a while, particularly the pattern of the seam, I have a few questions. What type of infill are you using? how many outer wall loops? How much infill overlap (or whatever it is called)?

Also what happens if you rotate the part on the bed 90 degrees so the seam is on a different axis? Or maybe 45 degrees? This will make sure it’s not some sort of mechanical issue in one direct that shows up in this specific situation.

I know that all seems random but those are what I would check hah.

Issue seems to be following the seam when I rotate parts. in this particular example I am using 5% gyroid, if I switch to grid the defect is uniform along the part. This is just 2 walls, can't remmber infill overlap, I'll check tonight.

Duct tape.

Most probably PA. You should try adjusting it while printing using some g-code console. This way you get immediate feedback. What they often don't tell you is that pressure advance is not something you can calibrate once and forget, it's dependent on material, temperature, nozzle diameter and also a lot on feed rate and extrusion rate.

The need for PA and precise tuning is more pronounced the higher changes in extrusion rate you have eg, you print very fast or with wide or high layers.

Just play around with it a bit and I'm sure that you'll find a better value after some layers.

There are even macros that try to remove the feed rate dependency by effectively replacing every g-code that adjusts feed-rate by a combination of the original g-code pre-ceded by an adjustment of PA. I haven't tried them out yet though.

What's weird is the differences of the effect between the layers. Is the every layer the same or is the path different for different layers? Maybe post some images of the inside of the model.

This is a good idea. I will further add that Klipper lets you dick with the linear/pressure advance parameters mid-print via GUI with its Fluidd interface. Other systems probably have similar capabilities.

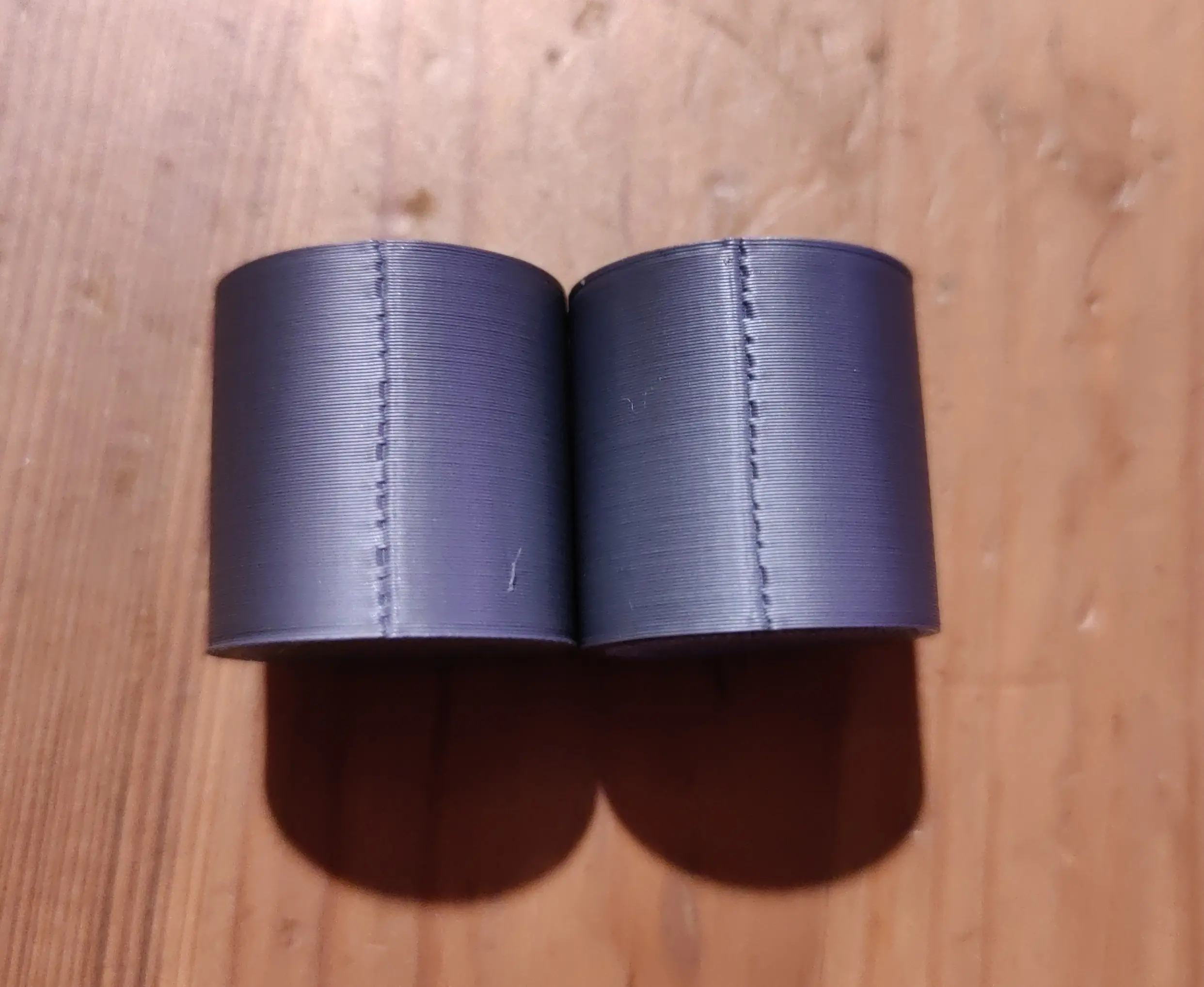

A good test model for this might be a thin walled hollow cylinder with the Z seam facing the user (i.e. out the door or front of the machine) only 2 layers thick or so. That sounds like it ought to make the issue visible quickly, and with minimum of wasted time and filament on infill (not to mention ruined parts).

_ I’m not using .... “retract on layer change”_

There's your problem.

No, I've tried with that enabled as well, same issue. This isn't before a layer change, it's when it goes from extruding the walls to extruding the infill.

But even without infill this happens. It's the end of the outer wall that doesn't connect to the beginning of the outer wall and it's not really fixed by reducing seam gap, so I'm not sure what's actually causing it.

What slicer?

I'm using orca slicer

Then I recommend Prusa Slicer.

This is likely a slicer issue.

Just tried, prusa slicer results in the same seam issue. I just loaded the default printer profile from anycubic and only changed gcode flavour from marlin to klipper (since I'm running klipper) and left the rest at default. Looks the same.

Have you tried checking the belts and all the bearings/rails for tightness and smoothness? It almost seems like layer shift at the seam, and if you compare both seams side by side, layer by layer, it almost seems like the print head shifts equally on both prints for any given layer (e.g. left print looks over-extruded while right print is under-extruded, next layer up, it flips and right print looks over-extruded while left print looks under-extruded).

If not the belts or other hardware, perhaps it's a flow issue. Do you know if the gross looking seams are the start or the end of the layer?