3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

I borrowed a thermometer from work that gets calibrated every couple weeks or so, and measured the surface of the bed of my printer. when the bed reads 90 in the printer firmware, the surface is only 78, but if I leave it for another 20 minutes or so both will be 100. My printer's temp probe is on the bottom, and the top has a magnet then spring steel. It takes a while for it to heat all the way through.

My chamber temps were also totally wrong so I changed the temp probe and that was fixed.

My abs problems went away, asa still curls but I'm leaning towards that being slicer settigs

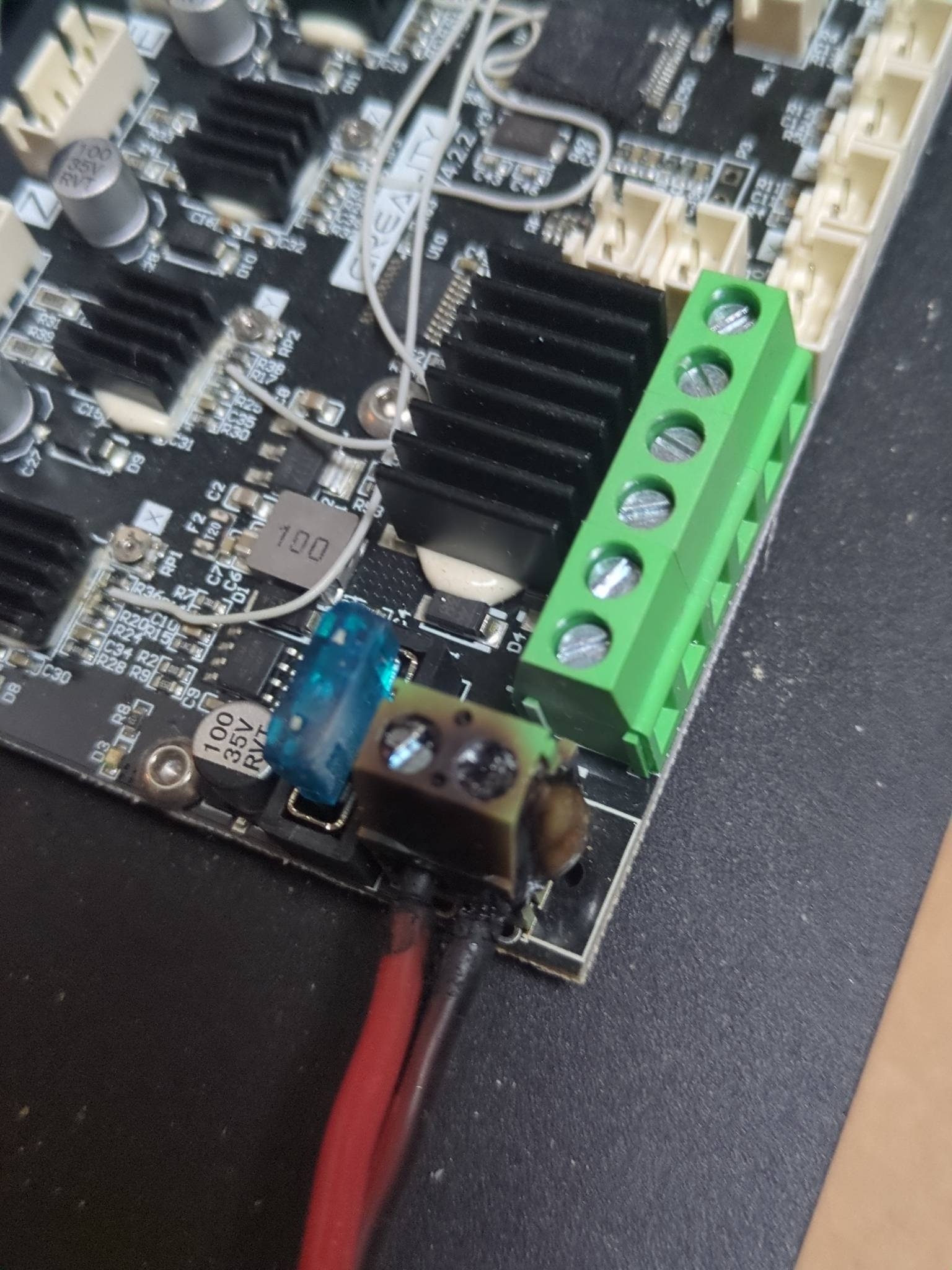

edit: i was also testing setting the temp too high then dropping it when the surface is at the target, but the plastic sheath on the crimped ferrules melted and the screw terminal bubbled. there might be stuff I could do to make it safer but I'm not inclined to chase it right now.

Holy shit dude this connector is an active fire hazard. You have to replace it, or the board, do not use the printer as it is now. Also remake terminals on wires. Do wires get hot as well? Something has too much resistance and acts as a heater, it's unsafe.

It should not burn like that even on full power. If your bed heater MOSFET ever shorts for any reason, it WILL pass through all power the fuse would let pass. If it burned like that and fuse didn't budge, imagine what can happen then. No wonder your bed takes a while to heat up when some of the power is wasted heating the connector.

makes sense. already have better boards lined up for both printers, pending time off work to install and rewire. Honestly I expect assorted smoke and burning from creality stock boards and the ones I've sold or given away were sent off with aftermarket controllers that the internet and myself have more faith in. This was one of the last 2 functioning stock boards I've ive been using for 3d printing experiments I don't want to do on more expensive gear.

Glad to read it!

Sorry to be such an alarmist, I just have a special kind of worry for this kind of stuff. Didn't mean to sound so condescending.

Stay safe!

Yikes you should consider replacing that screw terminal with a new one. With all the charring, it's possible that it's not making a great connection between the board and wire, which causes higher resistance and the terminal to heat up further.

I have more terminals to swap in but I'll be replacing the board anyway. The other identical board never did this but I also never tried pushing the limits on that one.

There must be something wrong with contact between traces/solder/connector/wire on this unit. May be many things, but high resistance is basically just a bad contact/too small area of contact.

For instance, one time an SKR board came to me with bed connector not soldered(!) to the board. I didn't notice for quite some time and have been using it, because the connector was seated strong enough. I noticed only because of the gradual heat damage to the board, and bed heating times getting longer and longer to the point of getting thermal runaway errors. Only then I inspected it in detail.

The other time on another SKR board, the connector was soldered, but slipped out of the solder which was the first time in my life I've seen anything like this. The solder cone was correctly formed, but I could slip the connector in and out of it. Guess something was wrong with surfaces of the connectors pins, maybe wrong metal on the outer layer so it didn't really get wetted by solder, guess I'll never know. Thankfully I've noticed this right before assembly.

Do not trust cheap DIY electronics that are suppossed to run long term unsupervised unconditionally, is what I'm trying to say.

I had an issue I caught early when I swapped my prusa from a Rambo to an skr mini, used the same power wires which didn't have ferrules, I got "lucky" that the power supply shut itself down, one wire had worked itself a bit loose, enough to potentially arc.

I've replaced everything with new 14 awg wire with solid ferrules and I inspect semi regularly, I trust my crimps here but I don't mess around with potential fire hazards. I think there's a tendency to think, oh it's low voltage, it's fine, but there's a lot of energy going through those wires, treat it with the same respect you would mains power. Take your time, double check everything, and invest in good crimping tools.