3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

Thanks!

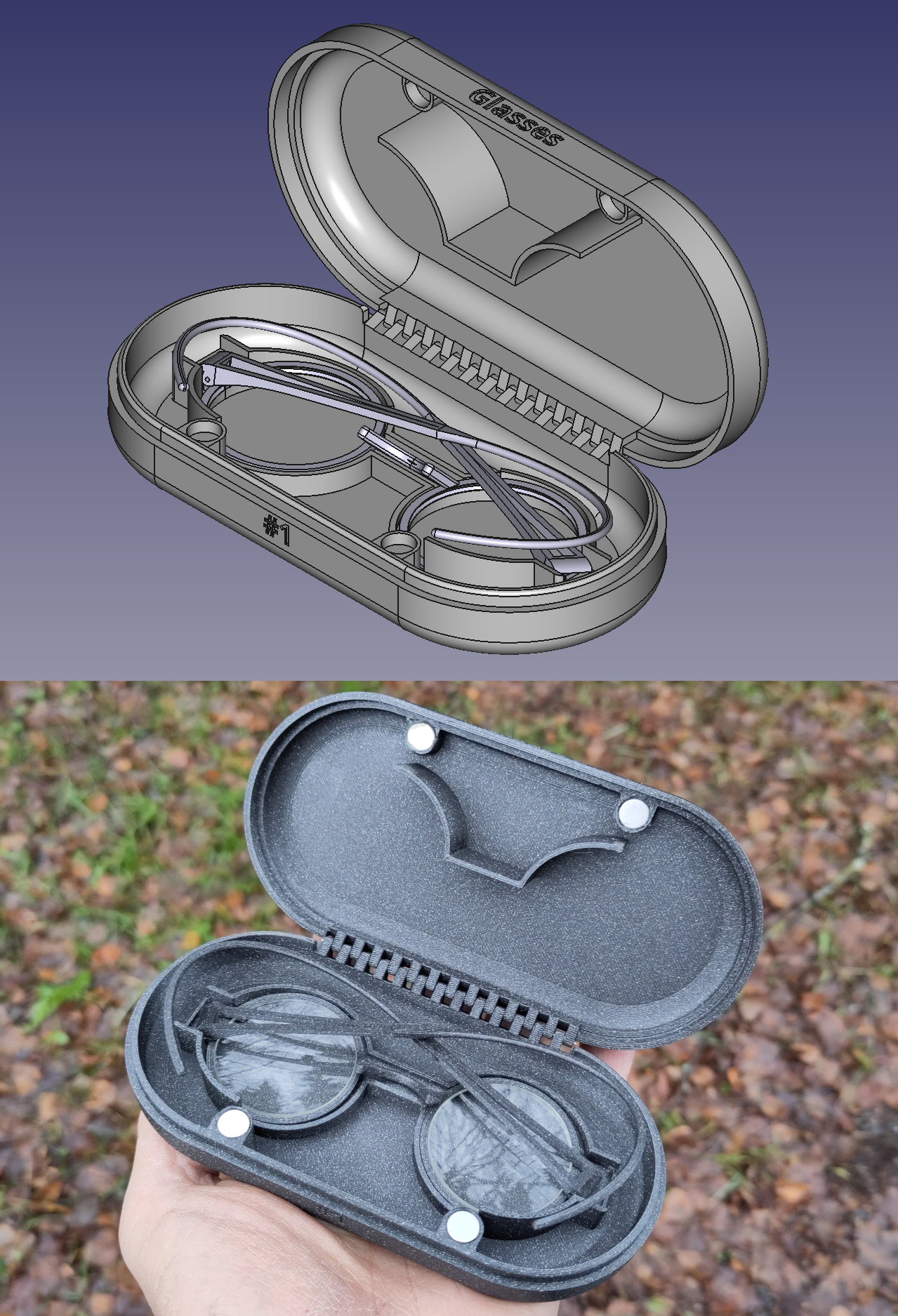

I just made one initial print but I didn't leave enough free play in the frame holder at the bottom of that case, so while it worked, it was kind of a pain to insert the frames into it. I widened the play from 0.4 to 1.5 mm and now there's zero usablility issue.

Another unexpected problem I discovered with that first print is that I couldn't tell the top shell from the bottom shell when the case was closed. I completely overlooked this and it turned out to be a massive PITA: 50% of the time, I would open the case upside down. Silly eh 🙂 It seems obvious in hindsight.

But I like the symmetry of it. So I added "engraved" text at the front edge to tell if the box is the right way up before opening, and put my name and a description of the particular correction in that case as a bonus.

The rest - stiffness, hinge, lid fit. magnet fit - came out okay the first time out. I'm getting really good at knowing the printer's tolerances in advance and leaving enough play for things that shouldn't assemble with an interference fit.