3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

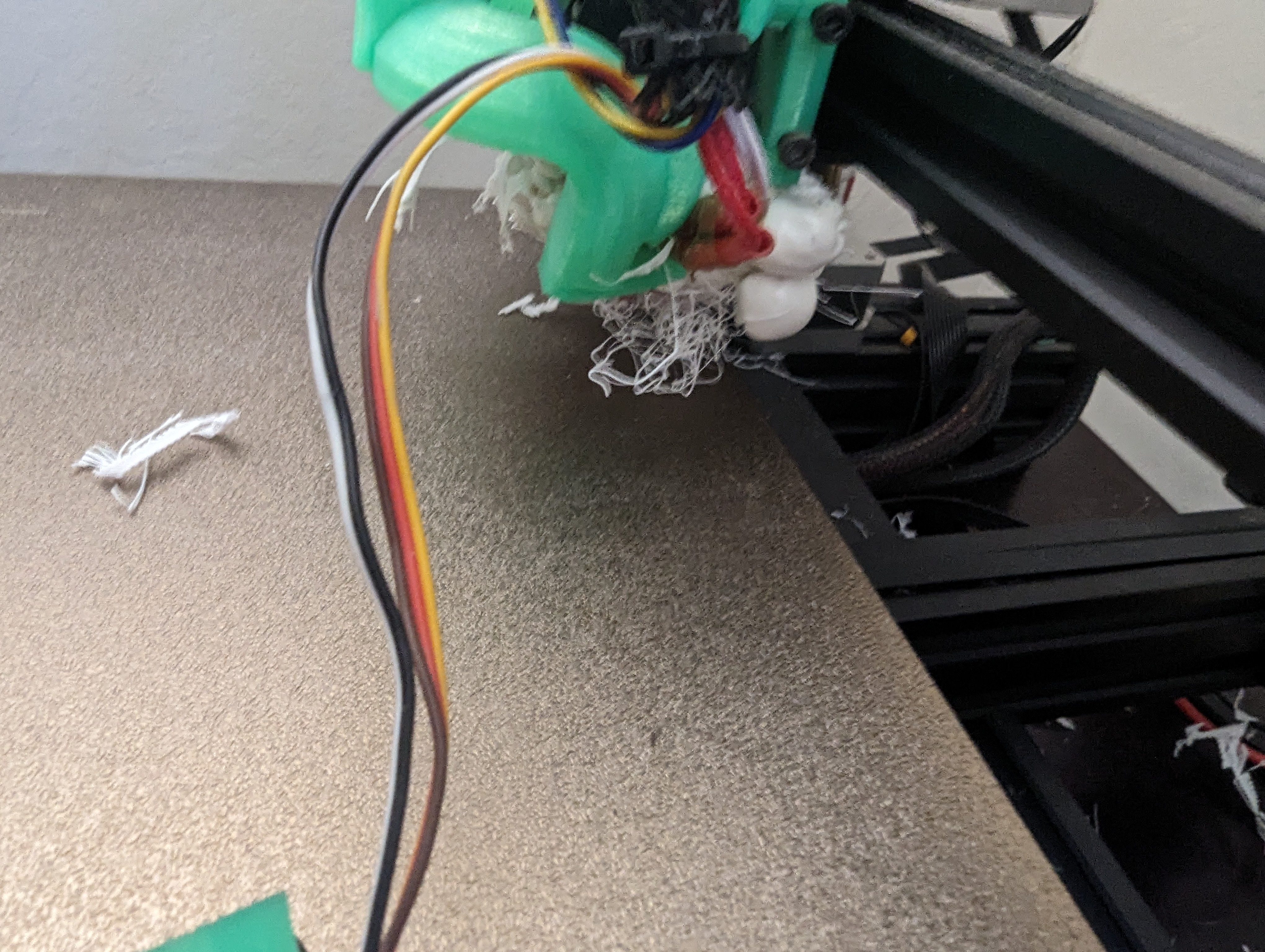

My worry is stripped threads and, in even if not, I think it's probably about time to let the poor thing retire (until I repurpose it into a filament extruder). It's served me far better than I expected.

I'm not sure what you mean by stripped threads. Metal is stronger than plastic, there's nothing the PLA blob can do to cause physical damage to your hot end besides damaging cables. And I don't know what threads would be exposed to even be damaged.

I mean if you're wanting to buy a new hotend by all means get one, but don't do so thinking you have to because of this. I almost wanna guarantee everything still works as long as your cables are intact.

True but, with pressure, water can cut metal. I'll be heat softening it with my PCB toaster oven to see if I can recover it. If it's just a leak, and no electrical damage, as you mention, it's probably ok.

Probably, I'll still get a new hotend, even if there's no breakage because I think that the PTFE feed tube is a bit of a weak link.

I would suggest setting your hot end to 80-90 degrees. At that temp, PLA becomes rubbery and pliable without being a melty burned out mess. You can then clip and remove the blob with care and proceed with breaking it down.

For other types of filament, you want to be just above the glass transition temperature and below the melting point. (usually it's a bit above your heated bed temperature.)