Sand a flat to create a D profile and then use a shaft collar and set screw

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

That you're looking for is called a flange mount. If you search your favorite search engine with "2mm flange mount" you'll find some results. I do wonder how much torque you'll be able to transfer, but given the shaft size I suspect you're not looking at big loads.

Rough sand the axis and add glue

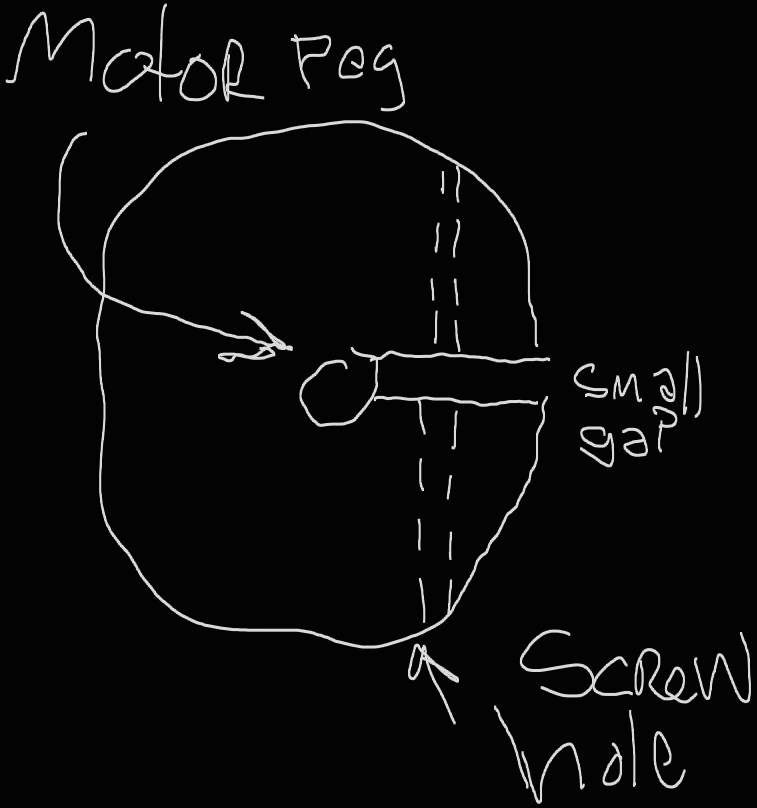

Instead of making the hole the exact size, make a small gap so you can use a screw and nut to clamp it down on the peg

But doesn’t that create an offset weight? My part will probably spin at several thousand RPM.

What is the plastic of your choice?

PLA, PETG, ... behave like a very slowly flowing liquid as such the print will deform/expand (creep).

I will be using PLA

For production parts look at other materials. Nylon might still be within the range of your 3D-printer.

For attaching: If you can't clamp then look at gluing it in place. If you need it detachable maybe drill a hole in the shaft and use a R-clip.

You can also tap and die the shaft on top. Make sure to use a left or right-handed thread depending on the rotation/load (thread is so that the rotation/force isn't unscrewing it).

Clamp it.

2mm is obviously too small for a grub screw. You're going to need a brass adapter or glue. Either way, it's probably not coming off (easily) when it's on there.