3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

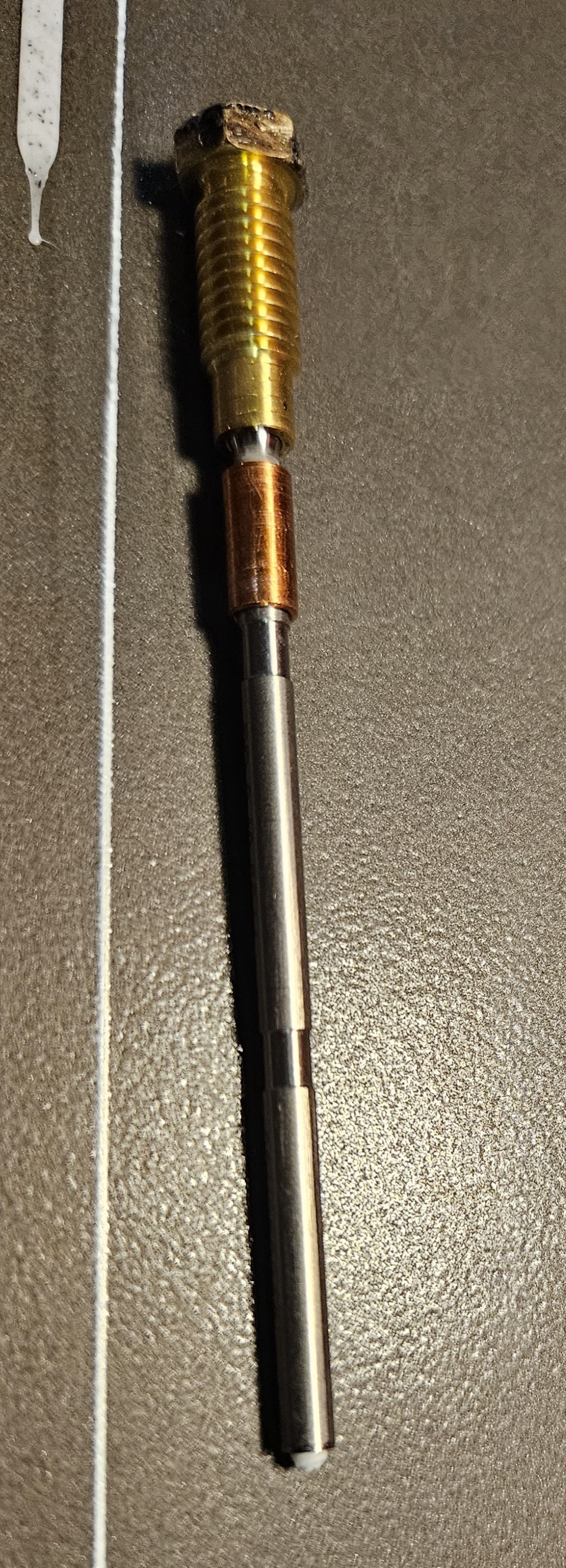

Blowtorch will heat this up way too hot.

Try to get it to a high enough temperature to insert filament to do a cold pull and repeat..

Electrical heat gun (paint stripper) is hot enough. Gas based torches will change the stiffness of your material and you will regret it.

Any particular reason? As explained above I regularly heat my hotend components to the point that they emit a light glow to remove all the plastic particulates and have never had an issue related to it.

You’re affecting the hardness of the metals if you’re heating them to glowing point, because you’re heat treating them. The actual consequence is probably minimal, but you could potentially be softening the brass tip which could affect the rate of wear. From skimming a few random online sources, brass is only work-hardened, so if the nozzle was previously hardened, you’re un-hardening it (apparently quenching from high heat only hardens ferrous metals like iron and steel?).

I see. Nozzles are cheap enough (when you get the cheap Amazon ones I do) so that I don't mind possibly eventually buying a few more to save myself massive amounts of time now, but it's good to know what the actual problem is