this post was submitted on 22 Apr 2025

190 points (99.0% liked)

Engineering

857 readers

22 users here now

A place to geek out about engineering, fabrication, and design. All disciplines are welcome. Ask questions, share knowledge, show off projects you're proud of, and share interesting things you find.

Rules:

- Be kind.

- Generally stay on topic.

- No homework questions.

- No asking for advice on potentially dangerous jobs. Hire a professional. We don't want to be responsible when your deck collapses.

The community icon is ISO 7000-1641.

The current community banner image is from Lee Attwood on Unsplash.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

I don't know how nuke plants are run, but maybe they'd just replace it entirely.

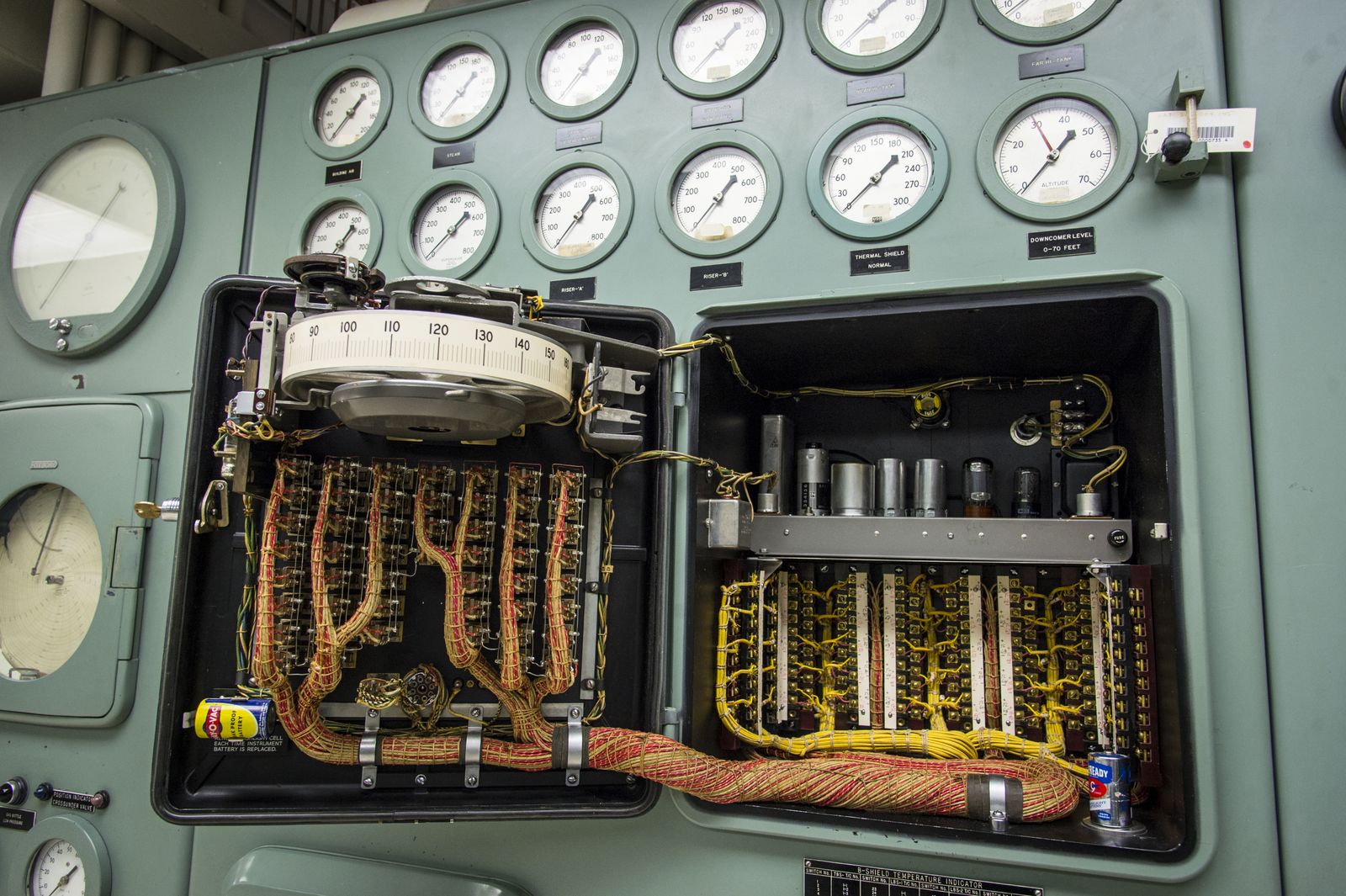

I don't know much about nuclear plants either but I do know a bit about wires and I think you are correct. It's very unlikely that one of these cables just snaps, look how they twisted the wires in that 'arm' so it can move and bend forming a nice elbow. So if it's corrosion, temperature, mechanical shock... it could affect other cables as well making advisable to replace the whole bunch altogether.

That said I've seen a very similar looking wiring, though very different machine, an electronic organ from the 60s. Among other issues there were some dead keys on one of the keyboards and the problem was the wires. I just ran a new bunch with an exactly looking cable, laced it the same way as the other bunches, and put it kind of hidden between them. It didn't stand out at all, most people would not notice at all.

That's pretty much how I'd expect it to go yeah, every electrician I've worked with has been super particular about wiring. Even having done my own in-field bodges on wire looms for equipment (just splicing a wire because I didn't have an available spare or time to redo the harness) it doesn't stick out, especially after all the cable wrap or zip ties.

That sounds fun. Looking at the picture again I feel like over time eventually the stress of opening and closing the panel would weaken something at least. Although tbf maybe it’s rarely opened